The Furnaces for the Future: the glass industry’s shared ambition for a low-carbon future

By 2050 the container glass industry aims to achieve a major revolution in the way we produce glass that is fit for a circular and climate-neutral economy. Brands and retailers alike have committed to ambitious sustainability goals, and as a material we use every day, glass packaging is playing a big part in this transition.

Whether you’re a manufacturer, a brand, or a consumer, reducing our carbon emissions is a shared challenge that requires innovative solutions from all of us. The joint Furnaces for the Future (F4F) vision represents our industry’s ambition to make glass packaging carbon neutral. In short, we’re exploring all possible paths to decarbonisation, such as biomass, hydrogen and electrification.

The Furnaces for the Future vision

To help secure the future of the European glass industry in a circular and climate-neutral economy, many ‘disruptive’ paths for decarbonising the production process are needed. European glass companies have been already investing significantly in the decarbonisation of their manufacturing processes and will continue investing to manufacture glass products fit for a resource-efficient, low-carbon society.

The industry is proud to produce healthy, reusable and infinitely recyclable closed loop packaging. Glass is a permanent material, meaning that can be endlessly recycled without loss of its intrinsic properties; it is inert and always remains healthy and safe for food grade packaging no matter how many times it is recycled. By addressing our industry carbon emissions, we can offer a fully climate-neutral packaging solution, in addition to being fully circular.

Research into innovative technologies

We have come a long way already in the decarbonisation how glass packaging is made. Every year, on average, the industry invests 610 million euro for plant upgrades, better energy efficiency and reduced CO₂ emissions – totalling 10% of production costs each year. Today, glass is 30% lighter, 70% less energy-intensive and emits 50% less CO2 than fifty years ago, but significant changes are needed to achieve our goal of zero carbon emissions.

The industry is committed to investment in sustainable innovation for years to come and large glass container manufacturers across Europe have joined forces to take on carbon emissions and charting new territory. In recent years, many initiatives have been put in place to reach the goals set by the glass industry, including:

- the launch of the Eco2Bottle – the climate-neutral glass bottle.

- launching a breakthrough new hybrid glassmaking furnace to run on 80% renewable energy.

- studying a variety of carbon-neutral energy systems that could be compatible with the glass melting process, to see how decarbonisation could be customised to local reality where plants are located.

- building hybrid furnaces using 50% renewable energy, assessing hydrogen, bioresources and process electrification alongside possible adaptations of existing melting furnaces to new energy sources.

- investing in new and modernised furnaces, with lower energy consumption and lower emission of greenhouse gases.

- building France’s first electric furnaces for luxury glass packaging – supporting high-end brands in reducing emissions and achieving a circular economy across their product range.

- developing new, modular furnace technology for glass production lines that can rapidly expand capacity when needed – with renewable energy sources and more recycled content.

- installing energy recovery systems for heating raw materials.

- working together with one of the world’s leading spirits companies to successfully utilize hydrogen glass melting technology to produce glass bottles while cutting greenhouse gas emission by more than 30%.

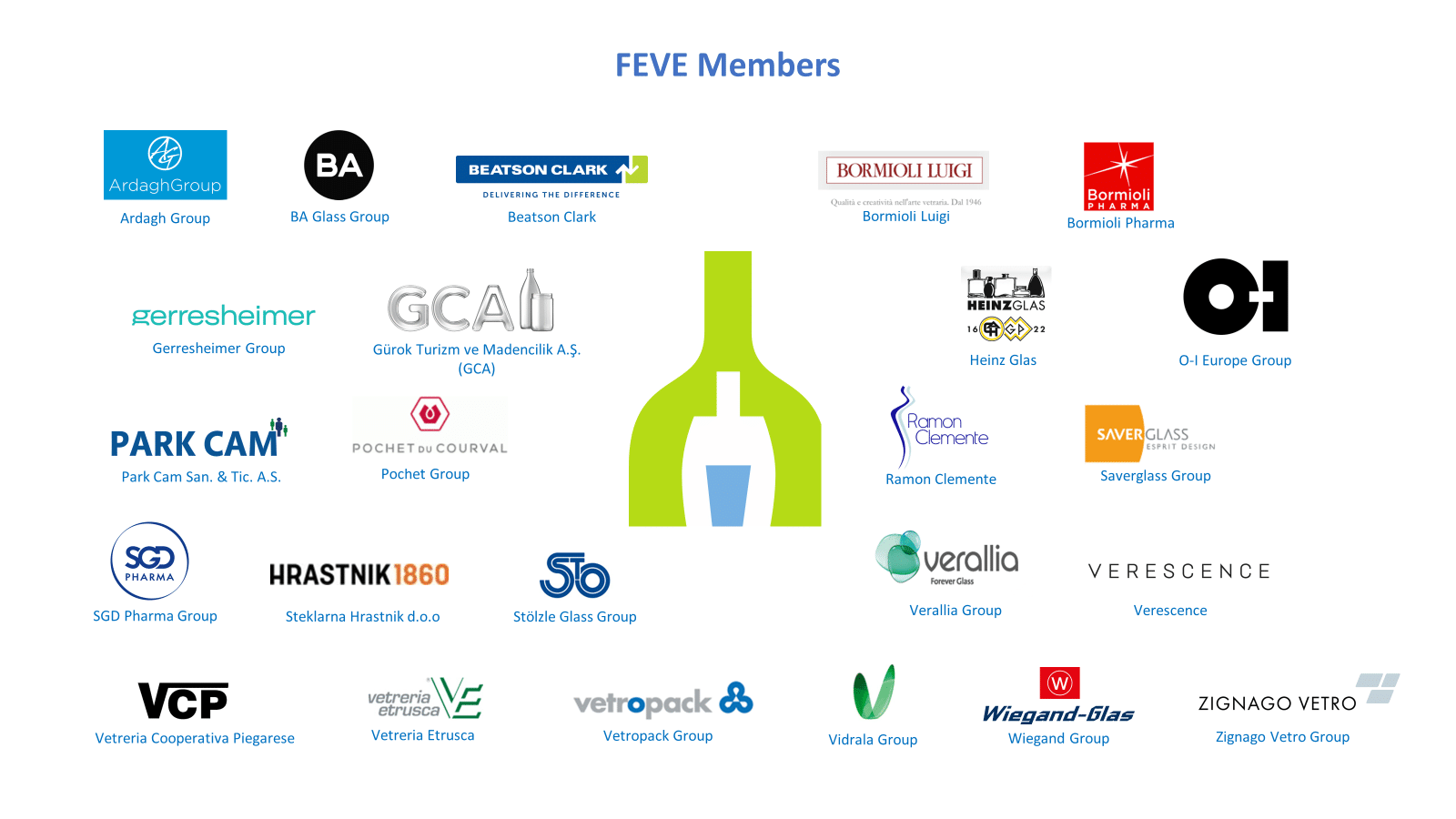

The whole industry stands behind the Furnaces for the Future vision, with glass container manufacturers from all over the continent signed on:

Members reflected as of June 2022